Museum grade glass-the core of museum display cases

Display cases are the core of museums,then glass is the core of display cases.What type of glass determines what security level and what presentation effect,thereby determines the integrated museum security and exhibition.For display cases to be customized for professional museum grade exhibition,protection and conservation for priceless museum collections symbolizing the civilization and evolution of the human beings,only customized museum grade glass in accordance with critical museum grade security and presentation is chosen and applied.

I.Museum grade protection by museum grade glass for museum grade display cases

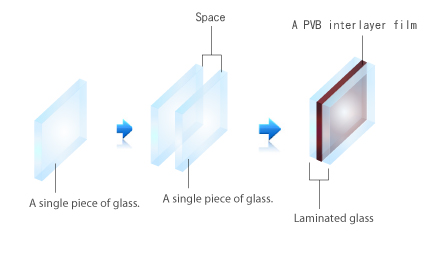

1.Only anti-bandit glass,i.e.laminated safety glass are selected for building museum grade display cases

Anti-bandit laminated safety glass and UV bonding technology create a safe and robust display space for museum display cases.

Customized museum grade glass with high-intensity PVB film laminated as interlayer between glass panes creates a high security level equivalent to being anti-bullet.In the event of intended heavy hit,PVB film interlayers will not be penetrated through and still hold the glass fragments in place to prevent glass break from scattering so it can effectively resist most physical attack to block possible damage to exhibited museum objects and possible hurt to museum staff and visitors.The museum grade glass needs to meet the most critical glass security criteria EN356 P4A at least.

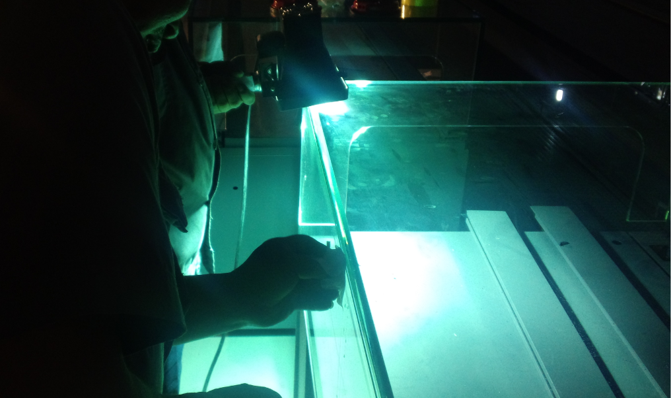

The ball drop test and axe hammer attack test is an effective way to verify the glass whether meet the standard of museum grade glass or not.The steel ball drop impact test-a 4.11kg solid steel ball to be dropped from 9 meters height onto laminated glass in a triangle for 3 times but no penetration through the galss,as well as the impact falling ball test- an axe hammer attack by a 2 kg head on a 900 mm long handle).

*Parameter of ball drop test*

*Ball drop test and test of resistance to manual attack*

2.With no mullion or frame, frame-less UV bonding is a process to bond glass panels together with clear and neutral UV adhesive then with the boning cured by dedicated UV curing light or UV activator.The exposure of UV light (ray spectrum 315-400nm) brings a flexible and stress-absorbing bonding which is stronger than glass itself for enough load bearing and totally free from mechanical fixings.

II.Museum grade conservation by museum grade glass for museum grade display cases

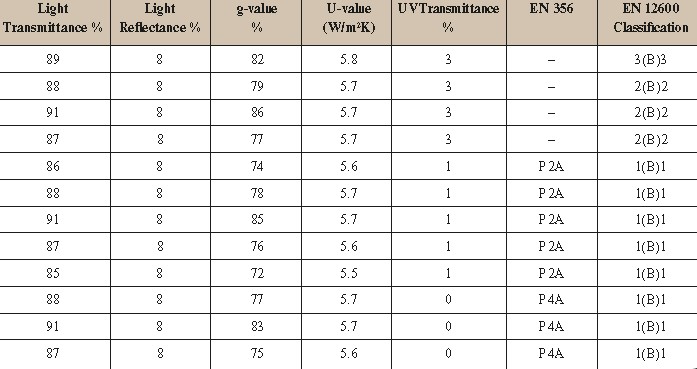

For natural light outside museum display cases and light from integrated lighting system within museum display cases,whether ultraviolet radiation with wavelengths shorter than 400nm or infrared radiation with wavelength longer than 760mm is invisible by eyes but it brings terrible damage to exhibits in additional to accumulating considerable heat.The PVB film interlayer for museum grade glass is able to effectively filter more than 97% ultraviolet radiation and infrared radiation as well as to prevent heat accumulation.

*Optical parameter*

III.Museum grade presentation by museum grade glass for museum grade display cases

1.Due to low iron content less than 0.015%, light transmittance for customized museum grade ultra-clear/optiwhite glass is over 97%.Ultra-clear/Optiwhite glass with low iron content virtually eliminates the green hue inherent in ordinary standard glass.

2.For bespoke non-reflectivity glass, the reflectivity from visible light between 400nm and 760nm is less than 1%.

3.Frame-less all-glass display space within museum display cases.

With no mullion or frame, frame-less UV bonding is a process to bond glass panels together with clear and neutral UV adhesive then have the boning joints cured by dedicated UV curing light or UV activator.Such a glass bonding technology creates a full vision with no sight obstacle on the basis of keeping enhanced anti-bandit performance.The special advantage of this glass bonding technology is to create invisible clear bonding joints,high stability and anti-bandit security,elegant edges and precise angularity.